In the construction industry, safety and precision go hand in hand. Heavy machinery like cranes, man lifts, piling rigs, and scissor lifts operate under intense loads and extreme conditions. One minor miscalculation or overload can lead to dangerous consequences — from costly equipment damage to life-threatening accidents.

This is where a Safe Load Indicator for construction equipment becomes not just important, but essential.

What is a Safe Load Indicator?

A Safe Load Indicator (SLI) is an intelligent safety device installed on lifting or load-bearing equipment to monitor the real-time weight being handled. It compares this data with the safe working load limit set by the manufacturer and alerts the operator if the threshold is exceeded.

Some SLIs also feature automated cut-off mechanisms, which disable certain machine functions when unsafe conditions are detected — providing an additional layer of safety.

Why Every Construction Site Needs an SLI

Whether you’re using a tower crane, EOT crane, boom lift, scissor lift, or a piling rig, the risk of overloading is real. Manual estimation of weight is often inaccurate, especially under site stress and time pressure.

Installing a Safe Load Indicator for construction equipment ensures:

- Operator and worker safety

- Extended equipment life

- Reduced risk of mechanical failure

- Improved compliance with safety regulations

- Faster and more confident operations

How Does It Work?

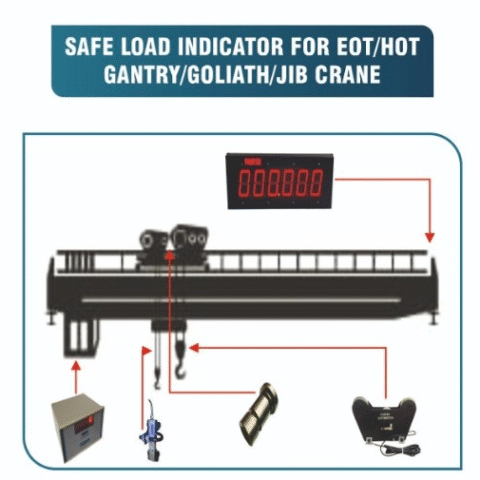

SLIs typically consist of:

- Load sensors (rope clamp, pin type, inline)

- A microprocessor controller

- Digital display unit

- Alarm systems

- Relay outputs for motion cut-off

As the load is lifted or moved, the sensors detect the force or weight and transmit data to the controller. If the load exceeds the predefined safety limit, the system raises an audio-visual alert and can disable critical operations like hoisting or extending the boom.

Applications of Safe Load Indicators in Construction Equipment

- Tower Cranes & EOT Cranes: Help prevent tipping or structural damage by monitoring load at different radii.

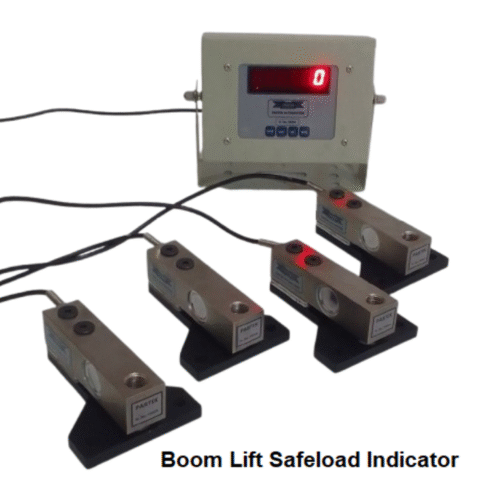

- Boom Lifts & Man Lifts: Protect operators by limiting upward motion in case of overload conditions.

- Scissor Lifts: Display real-time platform load and trigger alarms when limits are crossed.

- Piling Rigs: Ensure foundation machines do not over-apply force, keeping both rig and structure safe.

Made in India Solutions from Partek Automation

Partek Automation is a leading Made in India manufacturer of Safe Load Indicators, offering reliable and rugged systems designed for Indian site conditions. Our SLIs support a wide voltage range (12VDC, 24VDC, 100–260VAC), offer easy installation, customizable sensor options, and cost-effective operation.

We provide purpose-built SLIs for:

- Jib Cranes

- Hot /Gantry Cranes

- Piling Rigs

- Boom/Man Lifts

- Scissor Lifts

- And more…