Clevis Pin Load Cell – Reliable Industrial Weighing & Safety Solution

In industries where lifting, weighing, and load monitoring are critical, accuracy and safety go hand in hand. The Clevis Pin Load Cell is a proven solution for precise load measurement in cranes, hoists, and heavy lifting machinery. At Partek Automation, a leading manufacturer from Jaipur, Rajasthan, we design and deliver industrial weighing & safety solutions that meet the demanding requirements of modern construction and manufacturing environments.

What is a Clevis Pin Load Cell?

A Clevis Pin Load Cell replaces the standard load-bearing pin in lifting equipment, allowing direct and accurate measurement of the load being carried. It works by sensing strain when the pin is under load, converting that strain into an electrical signal for display and monitoring.

Why Clevis Pin Load Cells are Essential

In applications such as cranes, winches, and lifting jacks, knowing the exact weight being lifted is crucial to avoid overloading. The Clevis Pin Load Cell provides real-time load data, helping operators work within safe limits and preventing costly accidents.

Partek Automation’s Clevis Pin Load Cell – Key Features

- High Accuracy – Ensures precise weight measurement for critical lifting operations.

- Robust Construction – Built with high-strength stainless steel to withstand harsh industrial environments.

- Easy Installation – Designed to replace existing load-bearing pins without major modifications.

- Custom Sizes – Tailored solutions to match specific equipment requirements.

Applications

- Tower Cranes – Prevent overloading by monitoring actual load.

- Hoists & Winches – Ensure safe lifting and handling operations.

- Industrial Machinery – Accurate weight measurement for production and safety compliance.

Your Trusted Industrial Weighing & Safety Solution Partner

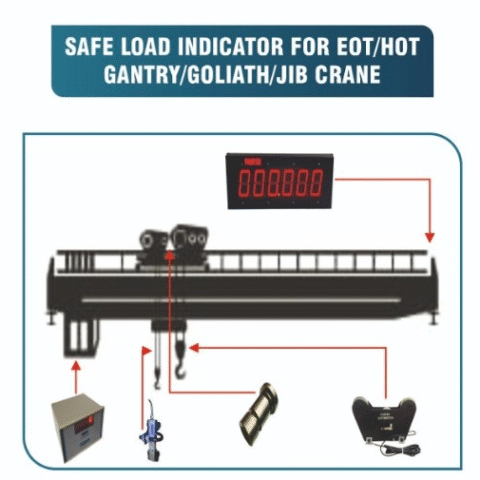

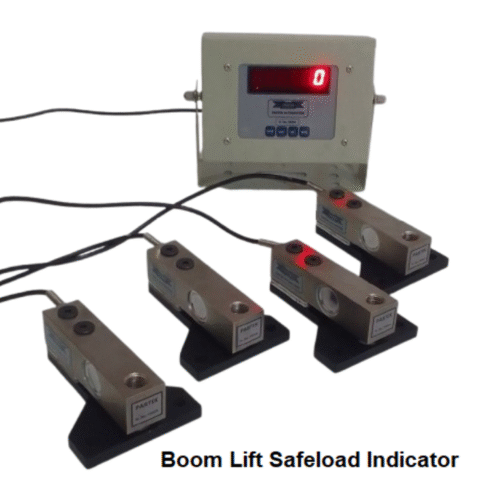

At Partek Automation, our Clevis Pin Load Cells are part of a complete range of industrial weighing and safety solutions. From Safe Load Indicators (SLI) to Overload Safety Devices, we ensure that every lifting operation is safe, efficient, and compliant with industry standards.

Made in India, Trusted Globally – With manufacturing based in Jaipur, Rajasthan, we combine indigenous engineering with quality assurance to deliver products you can rely on.